| ABOUT | NEWS | THE TEAM | RESIDENCIES | TECHNOLOGIES | RESEARCH | CONTACT |

| First published on www.designwalesforum.org |

| date: 31st March 2015 |

| author: Victoria Jones |

Haptic Modelling and 3D Printing Technologies

We recently launched another Makers Using Technology Residency call out, and thought that it might be useful to share how the technologies work and what they can do.

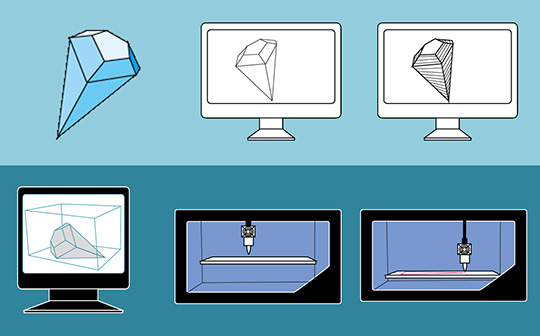

3D image to 3D object. Image courtesy of Design Wales.

Process

With all 3D printing, or as its sometimes known additive manufacturing, you need to have a 3D CAD (computer aided design) file. These files can be generated via most 3D CAD softwares, the one we use in the residencies is Freeform. Once a 3D CAD file is produced, the software 'slices' it into layers ready to 3D print. Whichever technology is used, 3D printing is always made in layers. The file is then transferred to another software package compatible with the 3D printing technology, and printed

Making a 'coil pot' in Freeform to demonstrate the characteristics of the software. Image: Diane Oliveira.

Haptic Modelling with Freeform

Freeform is a haptic modelling system. It allows the user to make irregular and organic forms similar to ones that can be made with real clay. A user can 'feel' the making process through haptic feedback from the omni-arm used to drive the software. The contours and textures created virtually, can be felt in the real world. Initially this is an extraordinary experience, but with repeated use you get used to it.

The virtual clay can be made soft or hard. Clay can be added to or 'carved' away. When soft, the clay can be manipulated with tools resembling the tools used by ceramists. When hard the clay tools resembling tools that stone carvers use can be used to chip away forms.

Forms can be mirrored, duplicated, embossed, created from 2D drawings... the possibilities are almost endless.

Made with a Material Extrusion or FDM 3D printer

FDM (Fused Deposition Modelling) or Material Extrusion, forces material (usually a polymer) through a heated nozzle. The 3D form is created by layers added on top of each other.

In the Makers Using Technology residencies, we use a Makerbot to enable the residents to have quick and cheap versions of whatever that are making. This is a 'lo-fidelity' technology. In the past some of our residents have liked the 'steppy' finish that the Makerbot affords and integrated it into their work.

Image: Diane Oliveira.

Image: Diane Oliveira.

Projet

By contrast, the Projet printer is our 'high fidelity' printer. It prints objects in layers with a resin supported by wax. This means that it enables objects which would be time consuming or impossible to be made by hand, to be easily created. The wax supports are simply melted away in an oven, leaving complex forms in the resin.

Image: Diane Oliveira.

Image: Diane Oliveira.

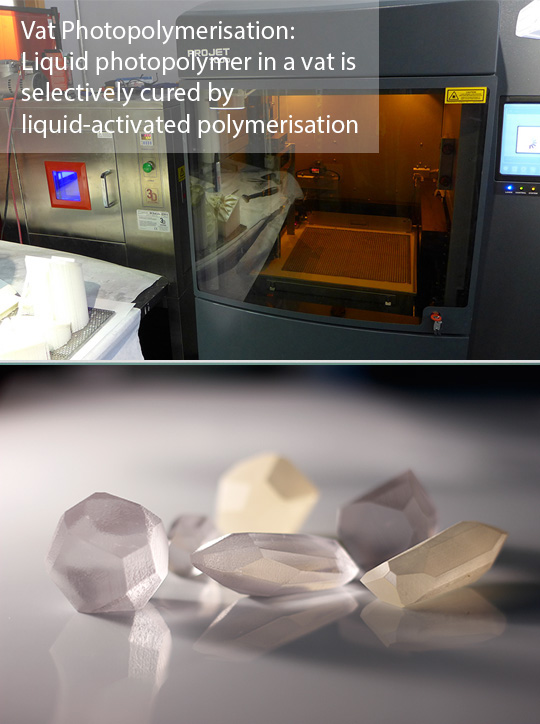

SLA

Stereolithography or SLA, prints objects via a bath of resin. A lazer beam darts around inside the bath, hardening the resin to make the object. Eventually the form emerges from the bath of resin. This technology can be used to create complex forms but not as intricately as the Projet as the support structure is also SLA and brittle.

Z-Corp

The Z-Corp printer works similarly to the SLA printer, except the lazer darts through a bath of sillica powder. It doesn't print a support structure and objects made with technology have the look and feel of ceramics. Due to its fragile nature, objects made with the z-Corp need to be hardened via coating or infiltration.

TweetThe residencies are being offered by Design Wales Forum, and have been funded by the Arts Council Wales through the lottery fund, and the National Centre for Product Design and Research.

Caiff y cyfnodau preswyl eu cynnig gan Fforwm Dylunio Cymru ac fe’u hariennir gan Gyngor Celfyddydau Cymru drwy’r gronfa Loteri a’r Ganolfan Genedlaethol Dylunio Cynnyrch ac Ymchwil.